Steel Testing

Steel Testing

IS 1786 – 1985 standard covers the requirements of deformed steel bars and wires for use as reinforcement in concrete, in the following three strength Grades:

- Fe 415

- Fe 500, and

- Fe 550.

NOTE :

The figures following the symbol Fe indicates the specified minimum 0.2 percent proof stress or yield stress in N/mm2.

- Lorem Ipsum is simply

- Printing and typesetting

- Has been the industry

- Printing and typesetting

- Lorem Ipsum is simply

- Has been the industry

This test helps in determining the ductility, but it cannot be considered as a quantitative means of predicting service performance in bending operations. The severity of the bend test is primarily a function of the angle of bend and inside diameter to which the specimen is bent, and of the cross-section of the specimen.

These conditions are varied according to location and orientation of the test specimen and the chernical composition, tensile properties, hardness, type, and quality of the steel specified.

Test Method: IS: 1599-1985, IS: 2329-2005, IS: 3600 (P-5,6)1983

The elongation is the increase in length of the gauge length, expressed as a percentage of the original gauge length. In reporting elongation values, give both the percentage increase and the original gauge length.

Test Method: IS: 3600 (P-3)1989

This test helps in determining the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen’s cross-section starts to significantly contract.

Test Method: IS: 1608-2005

Yield strength is the lowest stress that produces a permanent deformation in a material. In some materials, like aluminium alloys, the point of yielding is hard to define, thus it is usually given as the stress required causing 0.2% plastic strain.

This is called a 0.2% proof stress.

The purpose of re-bend test is to measure the effect of strain ageing on steel.

Test Method: IS: 1786-1986

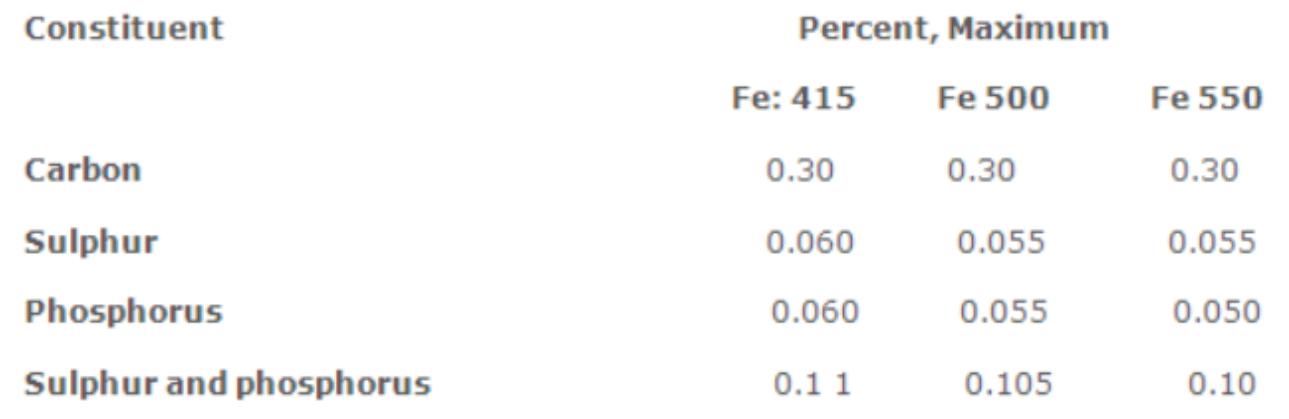

The ladle analysis of steel when made as per relevant parts of IS : 228 shall be as follows:

Other Services

Adhesive Testing

Water Testing

Cement Testing

Soil Testing

This laboratory is best of concrete testing this is nabl good service and good behavior every staff and senior person

Anand Kumar

Best Material Testing Laboratory in Navi Mumbai!

SKG Project & Engg. Pvt. Ltd., have a state of art Material Testing Laboratory in Mumbai.