All Products

- Home

- All Products

Aggregate Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

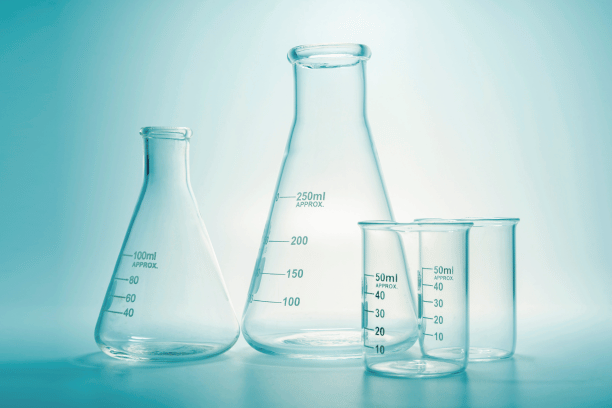

General Lab Equipments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

Moisture Meter

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

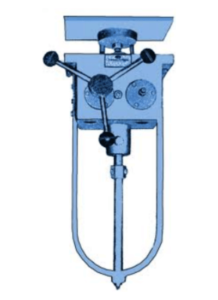

Soil Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

Bitumen Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

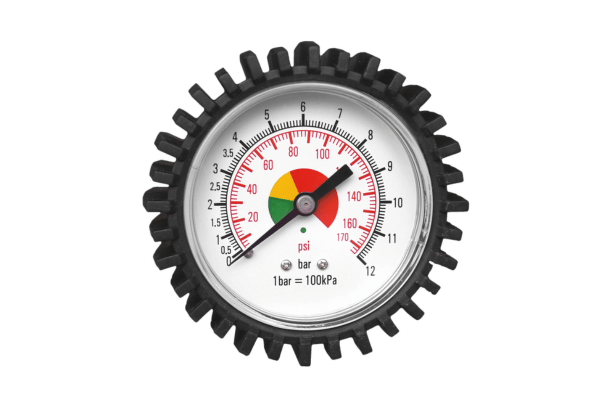

Measuring Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

Road Pavement Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

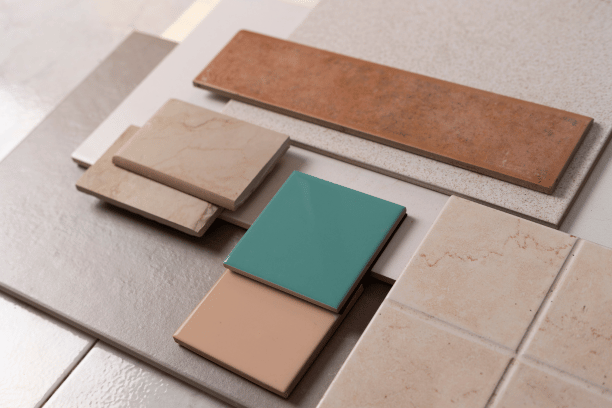

Tile Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

Concrete Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

Non Destructive Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

Rock-Testing-Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

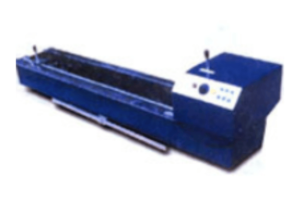

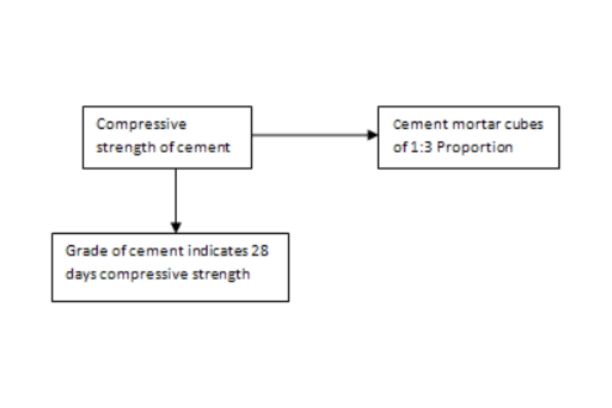

Cement Testing Instruments

The Roofing Repair Services of Company keep you protection keep you moving forward the best of roof.

We Ensure Accuracy & Reliability

Customization

100% SATISFACTION GUARANTEED

Good After-Sales Services

On Time Guarantee

Quality

The Quality Policy of SKG Project & Engg. Pvt. Ltd. (SKG) is to achieve self and customers’ satisfaction by providing reliable, consistent, test results of building materials in accordance with national / international / customer specific standards and good professional practices, as per the needs of its customers.

SKG follows good professional practices by use of appropriate tests / methods, standard reference materials, calibrated equipment, and trained personnel and shall endeavor to provide efficient services to its customers and take actions to enhance their satisfaction.

SKG is committed to improve services provided to customers complying with requirements of regulatory bodies and providing resources for quality services and training to all employees to be aware of Quality management system and implement quality policy and procedures in their work.

SKG is further committed to be fully responsible and Accountable towards successful implementation of quality management systems by meeting the requirements of ISO/IEC9001:2008.

What our happy customers are talking

Best experience with testing of construction material and chemicals. Very cooperative, understanding and efficient employees

This laboratory is best of concrete testing this is nabl good service and good behavior every staff and senior person

Good place to Test Materials.